You are here

Optical Fibers

Introduction :

The technology studied and implemented in the laboratory for the realisation of air-silica microstructured fibres (or PCFs) is based on a technique called "stack and draw". This technology is developed at the laboratory since 1998 and allows us to answer all requests, from academic or industrial, with recently an increase of the degree of complexity. XLIM also has all the equipment necessary to design, fabricate and characterize the PCFs and the more conventional fibres made by MCVD.

The technology studied and implemented in the laboratory for the realisation of air-silica microstructured fibres (or PCFs) is based on a technique called "stack and draw". This technology is developed at the laboratory since 1998 and allows us to answer all requests, from academic or industrial, with recently an increase of the degree of complexity. XLIM also has all the equipment necessary to design, fabricate and characterize the PCFs and the more conventional fibres made by MCVD.

Processes

The XLIM laboratory has a world recognized expertise in the field of the new generation of optical fibres. These fibres made with processes fully controlled are also a fundamental element of the work developed by the two research teams "fibre photonic" and "GPPMM." Finally, this platform is part of a scientific interest group namely GIS - GRIFON, national platform of the CNRS for optical fibres, whose other partners are PhLAM (Lille) and LPMC (Nice).

The complexity of the realization of microstructured fibres is now based primarily on:

- Fibres presenting various dimensions of air-holes in the same structure : dimensions are in the range of some hundred of nanometers up to some micrometers.

- Thicknesses of the silica struts inside the fibre extremely thine : down to a few hundred of nanometers, allowing the air-silica fraction more than 96% (Application to the hollow-core PCFs).

These PCF realisations go through a process including different stages from the fabrication of capillaries (basic element of the structure) to the microstructured canes and then the final fibres, all steps fully made at XLIM.

Examples of optical fibres fbabricated by the research group "fibre photonic" and "GPPMM"

Fabrication facilities

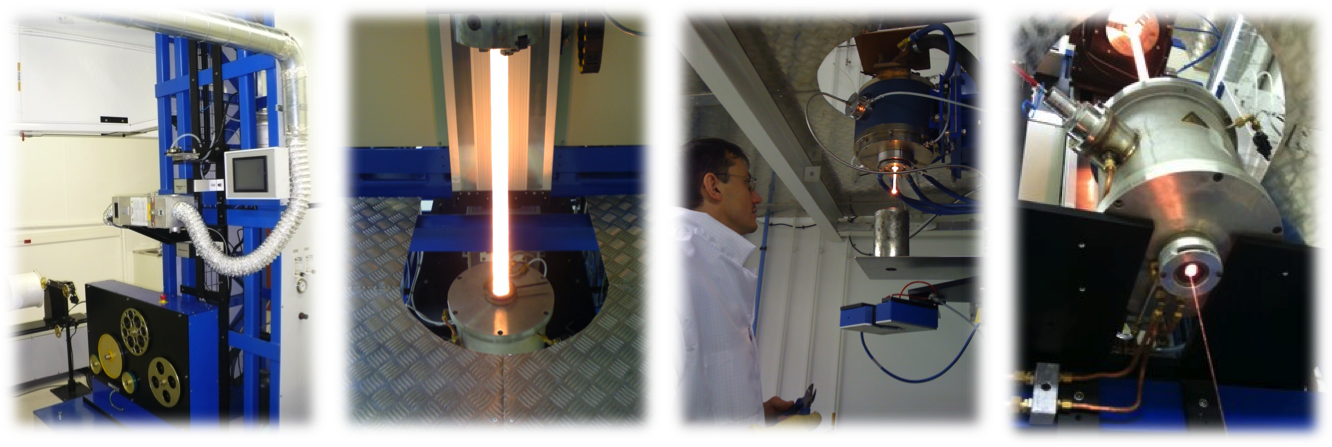

The fabrication facilities are composed of three drawing towers, two dedicated to the PCF applications and an other one to most upstream developments. Thanks to the high performances of these new equipments, we are able to control with fine accuracy all the drawing parameters: temperature with a stability or +/- 1°C, step by step digital servo-motors, massflow for gas flow inside capillaries ...

Pictures illustrating the fabrication facilities for optical fibres available at XLIM.

Technological research also focuses on:

• The incorporation of semiconductors nanoparticles, metal and rare earth ions inside fibres

• The "power" technologie : development of a process using powder materials, application to the production of structures made of different materials (glass, metals ...)

• The technologie of the reverse Dip Coating : fabrication of preforms using an original process based on a Sol-Gel approach

• The development of a bench for optical glasses fabrication - application of new materials for optical fibres

Are also available at the laboratory an Horizontal lathe for preform realisation, as well as different characterization equipment: a measuring profile of refractive index of the fibres, a system for measuring the chromatic dispersion, a scanning electron microscope and as a whole classical characterization systems (spectrum optical analyzer, continuous and pulsed laser sources ...).

Collaborations :

• Local : SPCTS, LEGRAND, Photonis, France Paratonnerre, GLOphotonics …

• National : Phlam (Lille), LPMC (Nice), LVC (Rennes), IPGP (Paris), ESPCI (Paris), Myrabilia Fabrik, MEGGITT, AREVA, ANDRA …

• International : IPHT (Iéna-Germany), Silitec Fibre SA (Switzerland), Oregon (USA) …

UMR CNRS n°7252

UMR CNRS n°7252