- FR

- EN

You are here

OPTOPLAST

Plastic Optoelectronics Technology and Instrumentation (OPTOPLAST)

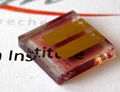

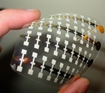

Objectives : The PLATINOM/OPTOPLAST technological facility at XLIM brings together a set of fabrication and characterization techniques dedicated to optoelectronic devices (photovoltaic cells, field-effect transistors, light-emitting diodes, sensors, etc). A specific instrumentation (glove boxes under inert atmosphere) allows the implementation of various components based on organic semiconductors, such as pi-conjugated polymers and small molecules. Both wet and dry processing technologies are compatible with a large choice of configurations and architectures. The physical characterization (morphology, optical and electrical properties) of the obtained devices aims at giving a better understanding of the involved mechanisms and the optimization of the architectures and of their functionalities.

- Contact / external inquiries : optoplast@xlim.fr

- Intranet (internal inquiries, booking of equipments, etc)

2016 Training course "Organic and Hybrid photovoltaic cells" - Cnrs Formation Entreprises / Réseau Nanorgasol

Session open for technicians, Ingeeniers, Researchers. Over 03-October to 05-October 2016. Download the training course flyer.

Dry processing technologies (physical methods)

- Thermal evaporation under vacuum : organic materials / metallic electrodes / interfacial layers (3 benches).

- Co-evaporation of organic molecules (1 set-up under inert atmosphere)

- Electron gun evaporation bench (metallic contacts) under inert atmosphere

- Ion beam sputtering (2 benches) : electrodes, transparent conductive oxides, inorganic materials

- Ion beam assisted deposition (IBAD)

Technologies from solution

- Ink and composite formulation, dispersion of nano-objects (ultrasonic probe)

- Deposition by spin-coating (2 equipments under air, 1 under inert atmopshere)

- Deposition by screen-printing

- Ink-jet printer DIMATIX DMP-2831 (Fujifilm)

Specific Equipments

- Glove box under inert atmosphere including wet and dry processing technologies (spin-coater and thermal evaporation benches).

- Glove box under inert atmosphere for optoelectronic device characterization (photovoltaic performance, external quantum efficiency, current-voltage characteristics, etc).

Materials and Devices Characterizations

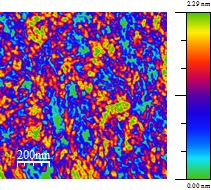

Morphology

- Mechanical profilometer DEKTAK XT

- Atomic Force Microscope CSI Nano Observer: AFM, C-AFM, and KPFM (double lock-in High resolution)

Optical properties

- UV-visible spectrometer (transmission) SAFA (300-900 nm)

- Reflectometer AGILENT Cary 300 (reflectometry, optical transmission) : 180 nm - 1010 nm, integrating sphere, for solutions and thin films

- Spectrophotometer Edinburgh Instrument FLS980 - Steady-state and Transient PL measurements (50 ps to 1 s)

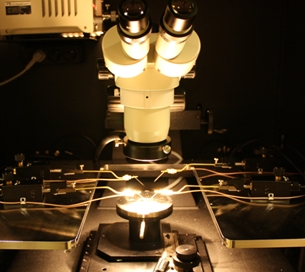

Electrical Characterizations

- 4-probe conductivity measurements

- Thermoelectric properties : Conductivity and Seebeck coefficient (77K - 400K, controlled atmosphere)

- Probing station - low frequencies (isolated)

- Dielectric Impedance spectroscopy (up to 120 MHz)

- Semiconductor characterization system Keithley 4200, Source-measure units (various Keithley 24XX - up to 5A)

Optoelectronic Characterizations

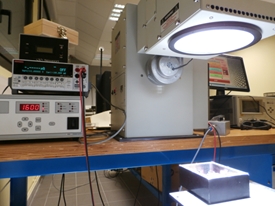

- Two AM1.5G solar simulators (Solarconstant PV275, ORIEL classe A) : under air or under inert atmosphere

- Two certified calibration cells

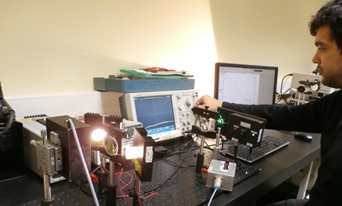

- Experimental set-up for electroluminescence (current-voltage, current-luminance, luminance spectrum)

- External quantum effiicency (EQE or IPCE) : under controlled atmosphere, under static or dynamic regime (lock-in)

- Transient photo-voltage and photo-current measurements (charge kinetics)

- LBIC / LPIV mapping of photovoltaic cells and modules

UMR CNRS n°7252

UMR CNRS n°7252